Product Description:

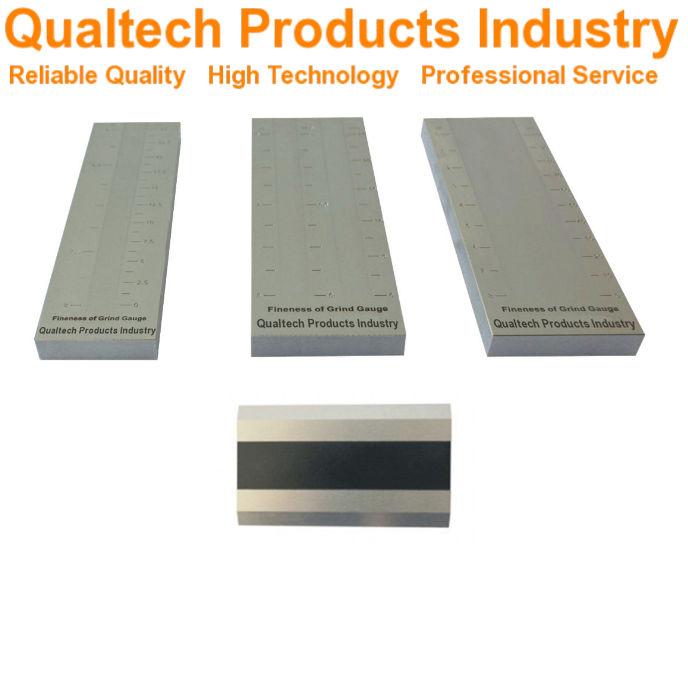

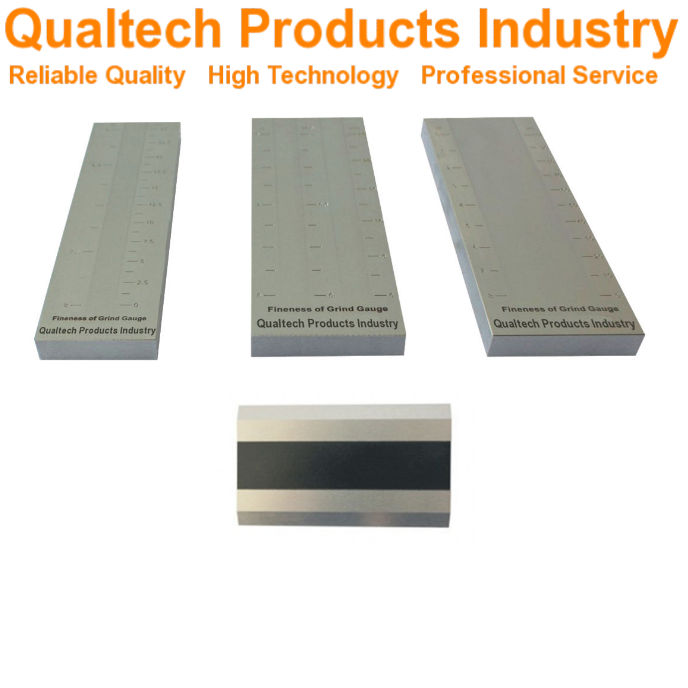

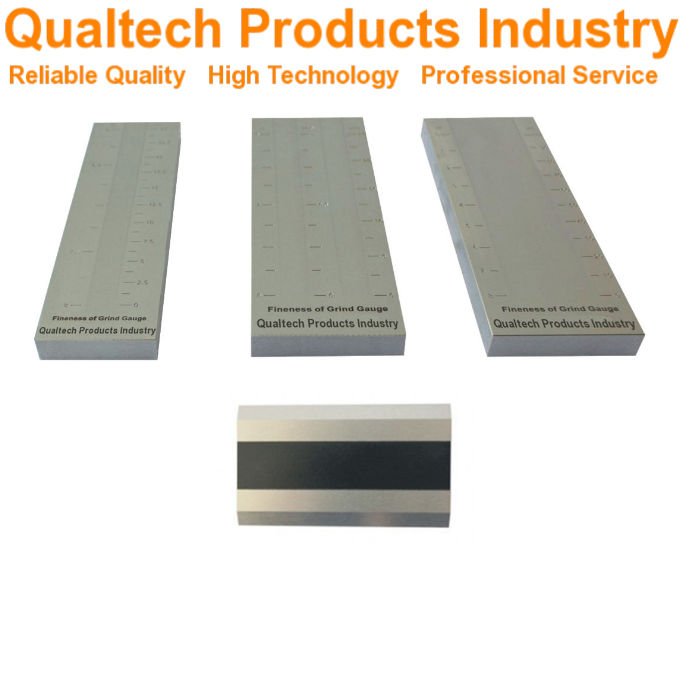

Qualtech Products Industry precision Grindometer is a professional Fineness of Grind Gauge to measure the particle size of suspensions including paint, coatings, ink, pigments, paper, ceramics, plastic, pharmaceuticals, food products and related sample materials. This professional Grindometer consists of a precision engineered hardened stainless steel Grindometer Base with a Single Channel, Double Channel or Wide Channel carved into its surface combined with a precision engineered Scraper Blade.

This professional Fineness of Grind Gage presents precision graduations in Microns, Mils, NS (Hegman) on the top surface to offer a user-friendly application and comfortable reading of sample test results.

This precision Grindometer and Fineness of Grind Gauge is used to indicate the Fineness of Grind or the presence of coarse particles or agglomerates in dispersions and suspensions – heterogenous mixtures containing solid particles to control the production, storage, and application of products which are milled or ground during the production.

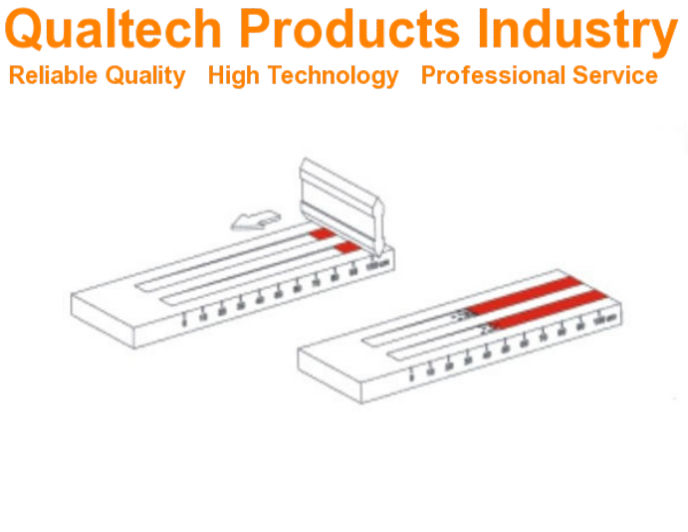

The liquid sample is poured into the deep end of the Channel or Groove and is distributed with the Scraper Blade towards the flat or shallow end of the Channel carved into the Grindometer until the largest particle size present in the sample liquid is equivalent to the depth of the groove of the Fineness of Grind Gauge.

This precision Hegman Gauge determines the largest particle size and possible irregularities present in dispersions and suspensions instantly, efficiently and with the use of only a very small amount of the liquid sample.

This professional Fineness of Grind Gauge is designed and engineered in accordance with international test standards including:

- ASTM D333 (Standard Guide for Clear and Pigmented Lacquers)

- ASTM D1210 (Standard Test Method for Fineness of Dispersion of Pigment-Vehicle Systems by Hegman-Type Gage)

- ASTM D1316 (Standard Test Method for Fineness of Grind of Printing Inks By the NPIRI Grindometer)

- ISO 1524 (Paints, varnishes and printing inks — Determination of fineness of grind)

- DIN EN 21524 (Paints and Varnishes – Determination of Fineness of Grind)

- DIN 53203 (Testing of paints and other pigment vehicle systems; estimation of the coarseness (respectively fineness) of dispersion by the grindometer)

- BS 3900-C6 (Methods of test for paints – Determination of fineness of grind)

- PR NF T30-046 (Paints, varnishes and printing inks - Determination of fineness of grind.)

- AS/NZS 1580.204.1 (Paints and related materials - Methods of test - Fineness of grind)

- FTMS 141a 4411.1

Fineness of Grind Gauge - Features:

- Precision engineered Fineness of Grind Gauge

- Precision engineered Scraper Blade

- High Quality Materials

- Hardened Stainless Steel to ensure longevity

- User-friendly Application

- User-friendly Sample Handling

- Easy Cleaning

- High-Precision Graduation in Microns, Mils, NS (Hegman) (Please specify when ordering)

- High Accuracy & High Precision

- Calibration Certificate

- Ergonomic Design

- Reliable Performance & Longevity

- Engineered in accordance with international test standards including ASTM D333, ASTM D1210, ASTM D1316, ISO 1524, DIN 53203, DIN EN 21524, BS 3900-C6, FTMS 141a 4411.1, PR NF T30-046, AS/NZS 1580.204.1

Hegman Gauge – Specifications:

| Model | Type | Groove Size (L x W) | Range | Graduation | Unit |

|---|---|---|---|---|---|

| QPI-HG1031 | Single Channel Grind Gauge | 140mm x 12.5mm | 0µm - 15µm | 0.75µm | µm |

| QPI-HG1032 | Single Channel Grind Gauge | 140mm x 12.5mm | 0µm - 25µm | 1.25µm | µm |

| QPI-HG1033 | Single Channel Grind Gauge | 140mm x 12.5mm | 0µm - 50µm | 2.5µm | µm |

| QPI-HG1034 | Single Channel Grind Gauge | 140mm x 12.5mm | 0µm - 100µm | 5µm | µm |

| QPI-HG1041 | Single Channel Grind Gauge | 140mm x 12.5mm | 0µm - 15µm | 0.75µm | µm & Hegman |

| QPI-HG1042 | Single Channel Grind Gauge | 140mm x 12.5mm | 0µm - 25µm | 1.25µm | µm & Hegman |

| QPI-HG1043 | Single Channel Grind Gauge | 140mm x 12.5mm | 0µm - 50µm | 2.5µm | µm & Hegman |

| QPI-HG1044 | Single Channel Grind Gauge | 140mm x 12.5mm | 0µm - 100µm | 5µm | µm & Hegman |

| QPI-HG1051 | Double Channel Grind Gauge | 140mm x 12.5mm | 0µm - 15µm | 0.75µm | µm & Hegman & Mils |

| QPI-HG1052 | Double Channel Grind Gauge | 140mm x 12.5mm | 0µm - 25µm | 1.25µm | µm & Hegman & Mils |

| QPI-HG1053 | Double Channel Grind Gauge | 140mm x 12.5mm | 0µm - 50µm | 2.5µm | µm & Hegman & Mils |

| QPI-HG1054 | Double Channel Grind Gauge | 140mm x 12.5mm | 0µm - 100µm | 5µm | µm & Hegman & Mils |

| QPI-HG1061 | Wide Channel Grind Gauge | 140mm x 37mm | 0µm - 15µm | 0.75µm | µm & Hegman |

| QPI-HG1062 | Wide Channel Grind Gauge | 140mm x 37mm | 0µm - 25µm | 1.25µm | µm & Hegman |

| QPI-HG1063 | Wide Channel Grind Gauge | 140mm x 37mm | 0µm - 50µm | 2.5µm | µm & Hegman |

| QPI-HG1064 | Wide Channel Grind Gauge | 140mm x 37mm | 0µm - 100µm | 5µm | µm & Hegman |

Fineness of Grind Gauge – Included items:

- Fineness of Grind Gauge

- Scraper Blade

- Beautiful Carrying Box

- Quality Certificate

- Carefully Calibrated

- Calibration Certificate

- User manual

- Extended Warranty

- Lifetime Support

Get information now on products, pricing, technical support and professional services.

One of our specialists will reply to your enquiry shortly. Alternatively contact us via the company details in the USA, in Australia or in the UK.