Product Description:

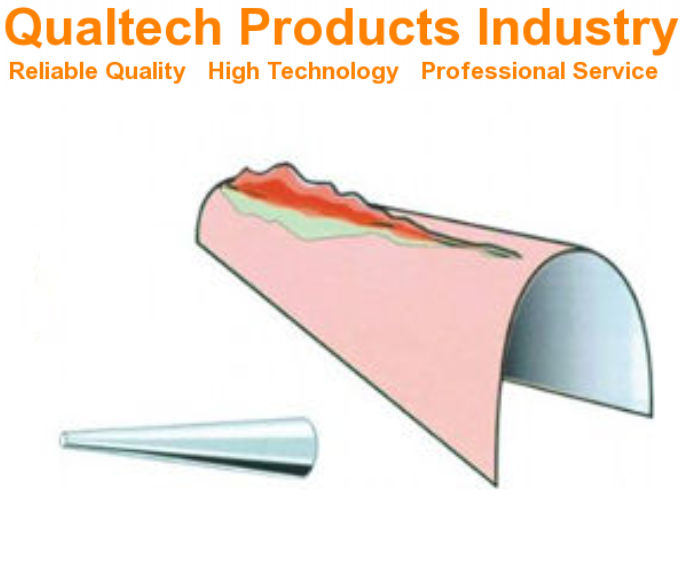

Qualtech Products Industry Conical Mandrel Bend Tester is an advanced Conical Mandrel Adhesion Test Instrument and Coating and Paint Film Test Instrument used to assess the quality and the performance of attached coatings and paint films respective their adhesive properties and their flexibility when exposed to bend-stress and deformation. When performing a Mandrel Bend Test this Conical Mandrel Bend Tester helps to determine the position on the Conical Mandrel at which a coating or a paint film starts to show signs of cracking or flaking due to the applied deformation-stress. The Mandrel Bend Test is a pass/fail or diameter to failure test method.

To perform a Conical Mandrel Bend Test the coated sample is placed into the Sample Holder and mounted with the Easy Switch Sample Mount of the Conical Mandrel Bend Tester. The coated sample is bent by rotation around the Conical Mandrel to instantly evaluate the performance of the coating attached to the substrate or sample surface.

The coated sample, usually, a coated substrate, an Aluminum Panel, a Steel Panel or a Iron Panel with a coating, can be bent in accordance with its individual width either along a small part of the Conical Mandrel or along the entire length of the Conical Mandrel.

The increasing diameter of the Conical Mandrel combined with the integrated high-precision graduation in inch and mm offers the precise identification of the adhesion characteristics and performance of cured coatings.

This professional Conical Mandrel Paint Film Bend Tester is designed and engineered offering an advanced design, an Easy Switch Sample Mount, high quality materials, a precision engineered Conical Mandrel, user-friendly application, user-friendly sample handling, high accuracy and high precision, an ergonomic design, reliable performance, longevity and much more.

This Conical Mandrel Bend Tester is an advanced, reliable and solid desktop Coating and Paint Film Performance Test Instrument made of high quality materials. This lever type Mandrel Bend Tester integrates a precision engineered Conical Mandrel combined with a high-precision Graduation and an Easy Switch Sample Mount offering a user-friendly application, easy sample handling and a reliable performance.

This professional Conical Mandrel Bend Tester is designed and engineered in accordance with international test standards including:

Conical Mandrel Bend Tester - Features:

- Newest Technology

- Advanced Conical Mandrel Bend Tester

- Instant Conical Mandrel Bend Test

- Precision engineered Conical Mandrel

- High-Precision Graduation in inch and mm

- Easy Switch Sample Mount

- User-friendly Application

- User-friendly Sample Handling

- High Accuracy & High Precision

- Ergonomic Design

- Reliable Performance & Longevity

- Engineered in accordance with international test standards including ASTM D522, ISO 6860, BS 3900-E11

Conical Mandrel Bend Tester – Specifications:

| Model | QPI-CMT2800 |

|---|---|

| Conical Mandrel Roller Diameter | Max 38 mm |

| Conical Mandrel Roller Diameter | Min 3.2 mm |

| Conical Mandrel Roller Length | 203 mm |

| Two precision scales with graduations in inches & mm | |

| User-friendly sample handling | |

| Precision Engineered | |

| Ergonomic Design & Longevity | |

Conical Mandrel Bend Tester – Included items:

- Advanced Conical Mandrel Bend Tester

- Accessories

- Quality Certificate

- Carefully Calibrated

- Calibration Certificate

- User manual

- Extended Warranty

- Lifetime Support

Get information now on products, pricing, technical support and professional services.

One of our specialists will reply to your enquiry shortly. Alternatively contact us via the company details in the USA, in Australia or in the UK.