ASTM D1894

Standard Test Method for Static and Kinetic Coefficients of Friction of Plastic Film and Sheeting

ASTM D1894 is a standard test method used to determine the static (µs) and kinetic (µk) coefficients of friction of plastic film and sheeting. These coefficients are important for understanding the slip properties of plastic films, which are of wide interest in packaging applications. The test results can be used for quality control purposes in film production and for predicting the performance of films in various applications.

Scope

This test method covers the determination of the coefficients of starting and sliding friction of plastic film and sheeting when sliding over itself or over other substances at specified test conditions. The procedure permits the use of a stationary sled with a moving plane, or a moving sled with a stationary plane. Both procedures yield the same coefficients of friction values for a given sample.

Appareil

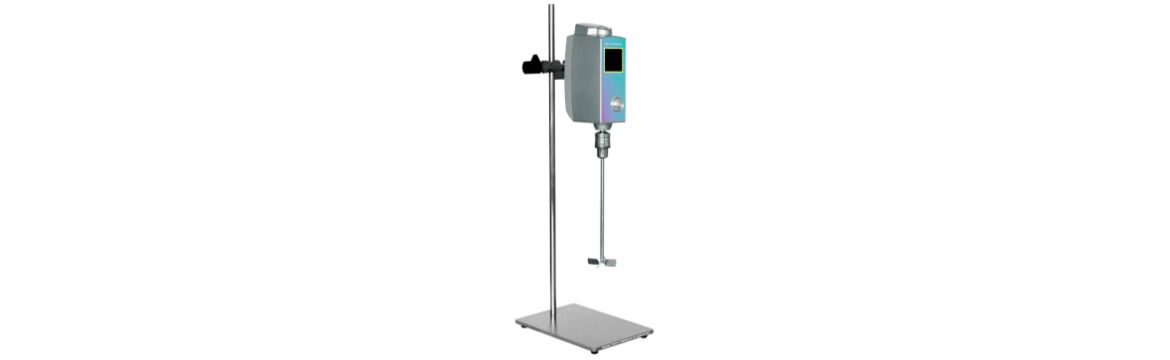

The apparatus for ASTM D1894 consists of the following:

A test frame with a crosshead speed of 150 mm/min (5.9 in/min)

A sled with a smooth, flat surface

A plane with a smooth, flat surface

A weight to provide the desired normal force

A load cell to measure the friction force

Procédure

The test procedure is as follows:

Clean the sled and plane surfaces.

Secure the film specimen to the sled.

Place the sled on the plane and apply the desired normal force.

Start the crosshead and record the initial peak force for static friction.

Record the average force during sliding motion over 127 mm (5 in) of travel for kinetic friction.

Calculations

The static coefficient of friction (µs) is calculated as follows:

µs = Fs / N

Fs is the initial peak force for static friction (N)

N is the normal force (N)

The kinetic coefficient of friction (µk) is calculated as follows:

µk = Fk / N

Fk is the average force during sliding motion for kinetic friction (N)

N is the normal force (N)

Report

The test report should include the following information:

Sample identification

Test conditions (speed, normal force)

Static coefficient of friction (µs)

Kinetic coefficient of friction (µk)

Précision

The precision of ASTM D1894 is as follows:

The repeatability (within-laboratory precision) is ±0.10 for both µs and µk.

The reproducibility (between-laboratory precision) is ±0.15 for both µs and µk.

All our test instruments and test equipment and production machinery are designed and engineered in accordance with recognized international test standards including ASTM, AATCC, CIE, DIN EN ISO, MIL, Ford, Renault, AS NZS, TAPPI and many more.

All our products are carefully calibrated to ensure the expected high accuracy of your research and your quality management stages and sample tests.

In addition, we are always here to assist with additional calibration services at our Calibration Centers.

Soutien

Le service client à toutes les étapes et la loyauté envers nos clients, un service professionnel et la fourniture de produits, d'instruments et de machines de la meilleure qualité sont quatre de nos principales priorités pour vous assurer que vous et vos équipes d'experts serez enthousiasmés et satisfaits de la qualité fiable de nos produits, instruments et machines. Qualtech Products Industry a développé et institué un système de qualité et est certifié ISO 9001:2000. Nous nous engageons à évaluer et à mettre en œuvre des améliorations de la qualité dans tous nos processus de recherche et de production en veillant à ce que "la qualité soit livrée à votre entreprise". Veuillez demander à nos équipes amicales de l'aide, plus d'informations, des détails et des services disponibles engagés pour vous apporter de vraies valeurs en tant que client important.