ASTM B212

Método de prueba estándar para la densidad aparente de polvos metálicos de flujo libre utilizando el embudo de caudalímetro Hall

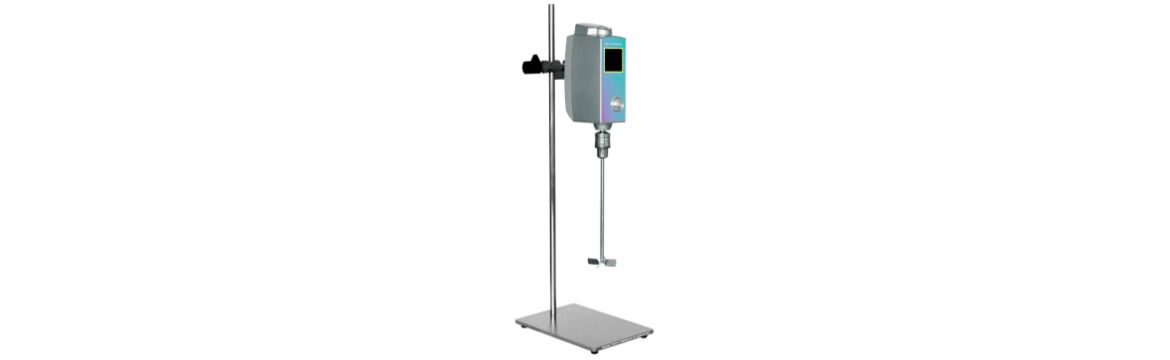

ASTM B212 is a standard test method for determining the apparent density of free-flowing metal powders using the Hall Flowmeter Funnel. The Hall Flowmeter Funnel is a device that measures the time it takes a specified mass of powder to flow through a funnel. The apparent density is calculated by dividing the mass of the powder by the volume of the powder that has flowed through the funnel.

The test method is applicable to free-flowing metal powders, and is not suitable for powders that are cohesive or sticky. The powder must be dried and free of contaminants before testing.

The test method is performed as follows:

The Hall Flowmeter Funnel is assembled and placed on a level surface.

The powder is weighed and placed in the funnel.

The stopwatch is started and the powder is allowed to flow through the funnel.

The stopwatch is stopped when the last of the powder has flowed through the funnel.

The apparent density is calculated as follows:

Apparent density = mass of powder / volume of powder that has flowed through the funnel

The apparent density is reported in grams per cubic centimeter (g/cm³).

ASTM B212 is a widely accepted standard test method for determining the apparent density of free-flowing metal powders. The results of the test can be used to compare the properties of different powders and to ensure that the powder meets the requirements of a specific application.

Here are some of the benefits of using ASTM B212:

It is a standard test method that is widely accepted by industry.

It is a reliable and reproducible method for determining the apparent density of free-flowing metal powders.

The results of the test can be used to compare the properties of different powders and to ensure that the powder meets the requirements of a specific application.

If you are working with free-flowing metal powders, ASTM B212 is a valuable tool for determining the apparent density of the powder. The results of the test can be used to improve the quality of your products and to ensure that your processes are operating efficiently.

All our test instruments and test equipment and production machinery are designed and engineered in accordance with recognized international test standards including ASTM, AATCC, CIE, DIN EN ISO, MIL, Ford, Renault, AS NZS, TAPPI and many more.

All our products are carefully calibrated to ensure the expected high accuracy of your research and your quality management stages and sample tests.

In addition, we are always here to assist with additional calibration services at our Calibration Centers.

Apoyo

El servicio al cliente en todas las etapas y la lealtad hacia nuestros clientes, el servicio profesional y la entrega de productos, instrumentos y máquinas de la mejor calidad son cuatro de nuestras principales prioridades para garantizar que usted y sus equipos de expertos estén entusiasmados y felices con la calidad confiable de nuestros productos. instrumentos y maquinas. Qualtech Products Industry ha desarrollado e instituido un sistema de calidad y cuenta con la certificación ISO 9001:2000. Estamos comprometidos a evaluar e implementar mejoras de calidad a lo largo de todos nuestros procesos de investigación y producción al garantizar que "la calidad se entregue a su negocio". Solicite asistencia, más información, detalles y servicios disponibles a nuestros amables equipos comprometidos para brindarle valores reales como nuestro importante cliente.