ASTM D1894

Standard Test Method for Static and Kinetic Coefficients of Friction of Plastic Film and Sheeting

ASTM D1894 is a standard test method used to determine the static (µs) and kinetic (µk) coefficients of friction of plastic film and sheeting. These coefficients are important for understanding the slip properties of plastic films, which are of wide interest in packaging applications. The test results can be used for quality control purposes in film production and for predicting the performance of films in various applications.

Scope

This test method covers the determination of the coefficients of starting and sliding friction of plastic film and sheeting when sliding over itself or over other substances at specified test conditions. The procedure permits the use of a stationary sled with a moving plane, or a moving sled with a stationary plane. Both procedures yield the same coefficients of friction values for a given sample.

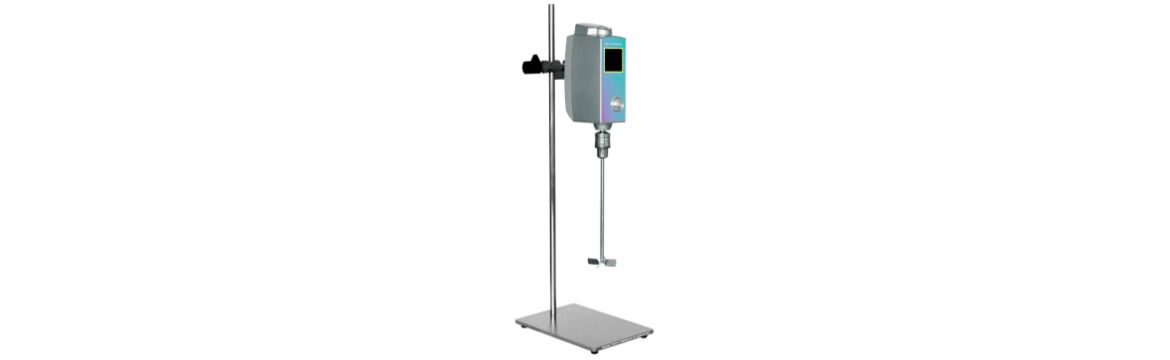

Apparatus

The apparatus for ASTM D1894 consists of the following:

A test frame with a crosshead speed of 150 mm/min (5.9 in/min)

A sled with a smooth, flat surface

A plane with a smooth, flat surface

A weight to provide the desired normal force

A load cell to measure the friction force

Procedure

The test procedure is as follows:

Clean the sled and plane surfaces.

Secure the film specimen to the sled.

Place the sled on the plane and apply the desired normal force.

Start the crosshead and record the initial peak force for static friction.

Record the average force during sliding motion over 127 mm (5 in) of travel for kinetic friction.

Calculations

The static coefficient of friction (µs) is calculated as follows:

µs = Fs / N

Fs is the initial peak force for static friction (N)

N is the normal force (N)

The kinetic coefficient of friction (µk) is calculated as follows:

µk = Fk / N

Fk is the average force during sliding motion for kinetic friction (N)

N is the normal force (N)

Report

The test report should include the following information:

Sample identification

Test conditions (speed, normal force)

Static coefficient of friction (µs)

Kinetic coefficient of friction (µk)

Præcision

The precision of ASTM D1894 is as follows:

The repeatability (within-laboratory precision) is ±0.10 for both µs and µk.

The reproducibility (between-laboratory precision) is ±0.15 for both µs and µk.

Alle vores testinstrumenter og testudstyr og produktionsmaskiner er designet og konstrueret i overensstemmelse med anerkendte internationale teststandarder, herunder ASTM, AATCC, CIE, DIN EN ISO, MIL, Ford, Renault, AS NZS, TAPPI og mange flere.

Alle vores produkter er omhyggeligt kalibreret for at sikre den forventede høje nøjagtighed af din forskning og dine kvalitetsstyringsstadier og prøvetest.

Derudover er vi altid her for at hjælpe med yderligere kalibreringstjenester på vores kalibreringscentre.

Support

Kundeservice på alle stadier og loyalitet over for vores kunder, professionel service og at levere de bedste kvalitetsprodukter, instrumenter og maskiner er fire af vores topprioriteter for at sikre, at du og dine ekspertteams vil være begejstrede og glade for den pålidelige kvalitet af vores produkter, instrumenter og maskiner. Qualtech Products Industry har udviklet og indført et kvalitetssystem og er ISO 9001:2000 certificeret. Vi er forpligtet til at evaluere og implementere kvalitetsforbedringer gennem alle vores forsknings- og produktionsprocesser ved at sikre, at "kvalitet leveres til din virksomhed". Spørg venligst vores venlige teams om support, mere information, detaljer og tilgængelige tjenester for at bringe reelle værdier til dig som vores vigtige kunde.